our Products

- Cold & Freezer Rooms

- Remote Cabinets

- Self Contained Cabinets

- Refurbishments

- Close the Case

- Aqualoop Refrigeration

- Multiplex Refrigeration

- Miniplex Refrigeration

Cold & Freezer Rooms

Creating That Perfect Layer Of Continuous Insulation Has Never Been Easier

Insulated Structures tailor-makes it’s panels for a cold room in all shapes and sizes. This makes us the service provider of choice when facilitating the design and manufacture of cold and/or freezer rooms.

Our panels are manufactured with “brilliant white chromadeck”, ready to install with our interlock and/or tongue & groove jointing systems.

Once the chromadeck panels have been constructed to specification, we then inject them with polyurethane foam. The chemical reaction that ensues causes the foam to expand, completely filling the interior space within the panel. This process creates a continuous layer of insulation that is not only rigid, but also fully adherent to the inner walls of the panel.

The Value Of A Cold Room With Polyurethane Injection

When insulating the walls, floors and/or ceilings of a cold room, most experts are aiming for that perfect thermal transmittance reading. This value (U-value) needs to be fairly low as it represents the rate at which heat transfers through matter.

Why Our Cold & Freezer Rooms Boast Far Superior Insulation

The U-value of our panels come in at a favourable 0.019 W/m²·K.

Our panels behave well against fire & don’t combust as easily as other insulation methods.

Our panels act as a moisture regulating membrane, being water impermeable & vapor permeable.

Our panels don’t attract rodents & other living things that could damage the insulation.

Manufacture & Installation

Our panels are manufactured and stored at our factory. Once installation commences, the panels get shipped and installed by our specialist team.

See our table below for technical specifications and for any further information, feel free to contact us on 011 462 2130.

| Dimensions | Features | Customisation |

|---|---|---|

| Panel Thickness – 40mm, 60mm, 80mm, 100mm, 120mm. | Door Type – sliding and/or hinged. | Meat Rail System -support integrated within panel. |

| Panel Width – up to 1200mm. | Floor Type – various available (application dependent). | Panel Finish – smooth or ribbed (galvanised steel). |

| Panel Height – up to 12 metres (thickness dependent). | Safety – doors come with emergency release. | Panel Colour – frost white / black. |

Polyurethane Panels

Panels are joined by high impact PVC interlock profiles that snap together easily to form a sealed joint.

The PVC used will compensate expansion and contraction due to temperature variation, preventing cracks and moisture penetration, which could result in reduction of insulation value.

Floors - Fabricated and Concrete

The inside floor finish of the fabricated floor is 2mm Aluminium Treated Plate or 0.8mm Galvanised Plate glued to a Marine Ply base.

Concrete floors are used for flush entry - no step up, and in permanent structures. Usually a recess of 150-170mm is used to accommodate the foam slab insulation and the concrete screed.

Meat Rails

Hot dipped galvanised or Electro Galvanised meat rails can be supplied and installed to client specifications. The meat rail support structure is integrated into the insulated panel.

Aluminium Chequer Plate

Aluminium chequer plates can be installed in freezer rooms or cold rooms as an option to protect panels from damage caused by scratching and light impact. Standard aluminium chequer plates are supplied are 1.6mm thick and 1250mm in height.

Remote Cabinets

Suited To Supermarket Environments

Remote cabinets are best suited for display of food & drink in a supermarket environment. They are able to work with any of our refrigeration systems and have good energy efficiency over extended use.

Benefits of our Remote Cabinets

Heat Distribution

Remote refrigerated cabinets are connected to external refrigeration systems, this results in any heat & noise being diverted outside the building, rather than running in-store.

Cabinet Line-Up

Units are manufactured to specification to fit particular areas in-store. We design and place the cabinets during the installation phase to suit our customers unique requirements.

Product Range

The Tyler & Slimline range allow for a broad spectrum of applications in-store. The range accommodates for anything from low island freezers to square upright units.

Self-Contained Cabinets

Self-contained refrigerated cabinets are convenient & suitable for various applications, offering simple "plug & play" operation.

Flexible By Design

Self-contained refrigerator cabinets are plug in and switch on 220v units. They are ideal for specialist applications and can easily be moved around to suit changes in the demographics of your customer base.

Plug & Play

A plug & play 220v self-contained refrigeration system that is easy to move around when necessary (i.e. changing the format of your store). Available in refrigerated or heated units.

Self-Evaporating

Any water condensation within the unit is evaporated through a heater element therefore no additional drainage is required (Ideal for specialist applications).

Modern Design

These cabinets boast a modern, upmarket design. Ideal for specialist areas of your store. They provide suitable application for pastry, deli, dairy and meat or processed meat.

Refurbishments

Full refurb costs around 60% of what you would expect to spend on new cabinets. Across several units, this equates to a large capital saving.

Keeping Things Fresh Is A Collaborative Effort

When it comes to refrigerated cabinets, you are looking at a maximum lifespan of approximately 10 years. It’s highly likely that during this period a store owner would need enhancements and, in some cases, a totally new cabinet.

New refrigeration cabinets are exposed to varying degrees of wear and tear; everything from foot traffic in-store, to the staff that engage or pack these cabinets can affect their overall lifespan. In order to combat the above as well as improve your cabinets service record, we have devised a three-tier refurbished refrigerator standard.

We understand that stores can’t afford to have their cabinets standing idle or out of service for extended periods of time and do our utmost to roll out refurbishments with maximum efficiency. Our technicians are trained to handle on-site cabinet enhancements and/or repairs, often putting in “night work” to ensure the least impact on a store’s day-to-day operations. Only in extreme cases where a complete overhaul (tier 3) is required, will a cabinet be taken off-site.

Tier 1 – Look & Feel (On-Site)

The first level of refurbishment focuses on the cosmetic enhancement of your refrigeration cabinets. Upon inspection the cabinet would be subject to minor recladding, a clean-up of the tub and shelves as well as new top hoods where applicable. This takes place through “night-work”, which is done on-site with minimal/no downtime on the cabinet itself.

Tier 2 – Part Replace (On-Site)

This level incorporates the cosmetic adjustments discussed within tier 1, however goes into further detail. The recladding on the cabinet is more comprehensive. Powder coated parts are resprayed and replaced where applicable. (Powder coating done off-site). Again level 2 is carried out as “night-work” as per tier 1.

Tier 3 – Full Refurb (Off-Site)

Tier 3 gets to the heart of your cabinet. We carry out a full refurbishment of the cabinet at 60% of the cost you would expect if you bought it new. Replacing all coils, L.E.D lighting as well as all the recladding and cosmetics outlined on the previous refurb levels. This level is a capital-saver for store-owners and greatly extends the life of the cabinet.

Turn-Key Solution For Corporation’s

We enter in to corporate agreements for the more complex cases where stores are running multiple refrigeration cabinets across the country. Our aim is to give corporations the utmost confidence that their cabinets will be taken care of.

From the minute the contract is in place corporations have exclusive access to services over and above our three-tier refurbished refrigerator standard. We become intrinsically involved with your stores refrigeration systems.

This could include things like storage for cabinets that are out of service, in need of refurbishment, as well as all the logistics around preparing new stores to launch with fresh products. Ultimately, we aim to provide an effective, turn-key solution to our partners within our realm of expertise.

Close the Case Cabinet Doors

With energy costs rising and food retailers looking to improve the shopping environment for customers, Insulated Structures has developed an effective solution to reduce the cost of in-store refrigeration while enhancing the customer experience.

Insulated Structures doors are easy to retrofit on in-store cabinets to reduce the energy required to keep chilled foods at the correct temperature.

Meanwhile, customers are able to clearly see and access the products on offer. Reduced energy requirements means smaller refrigeration plant selection for new stores. These savings will offset the cost of the doors. Up to 40% reduction in refrigeration requirement has been achieved.

Premium Airshield Doors

Standard Airshield Doors

Benefits of Close the Case Doors

Reduce energy consumption.

Up to 40% energy savings.

Extend product shelf life.

Double glazed argon filled void for better insulation.

Glass doors have an option of Mullion Lights.

Doors are spring loaded.

Less cold air spillage, warmer isles.

Solution for new and retro fitted on existing cabinets.

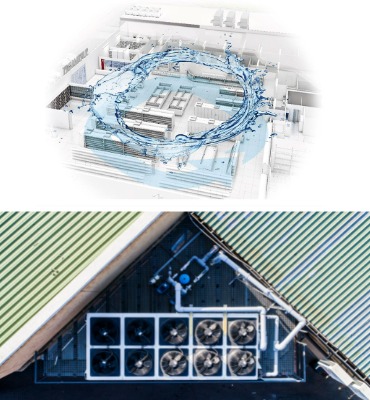

AquaLoop Refrigeration - Establishing A Closed Water Loop

Aqualoop is Insulated Structures high efficiency solution for managing cabinets that replaces the classic layout of compressor racks and long refrigerant distribution lines, with a system based on plug-in cabinets fitted with variable-speed DC compressors and cooled using a water loop.

The system consists of a compressor for each cabinet with a common waterloop.

The benefits of the system are as follows:

Energy Efficiency

Maximum energy efficiency at part loads is a result of continuous modulation, which moreover guarantees the best operating conditions for each unit, each independent of the others yielding up to 25% energy savings in comparison to other systems.

Excellent Food Preservation

A stable control temperature maximises both the quality of food preservation and customer satisfaction, eliminating fluctuations in product temperature.

Lower Operating and Maintenance Costs

Prevention of malfunctions and planning of maintenance using advanced preventive diagnostics algorithms, and complete monitoring of all operating conditions. A lower impact on the balance sheet due to significant energy savings.

Easy Installation

The showcases are ready to use, and simply need to be plugged in and connected to the water loop.

Other Benefits

The Multiplex Revolution

Supermarkets are one of the most energy-intensive types of commercial buildings. Significant energy is used to maintain chilled and frozen food in both product display cases and storage refrigerators. Perishable products must be kept refrigerated during display and for storage. Refrigeration is usually responsible for around half of a typical store’s total energy consumption bill. Compressors and condensers account for 60-70% of refrigeration energy consumption. The remainder is consumed by the case, freezer and cold room fans, display case lighting, evaporator defrosting, and for anti-sweat heaters used to prevent condensation from forming on doors and outside surfaces of display cases.

With this in mind selecting the type of refrigeration system suitable for your needs, needs to be considered carefully.

We have different options of solutions available when selecting your multiplex plant:

Plantroom building with equipment installed in a room supplied by the client.

6m or 12m container with refrigeration equipment inside the container.

All equipment comes in a weatherproof enclosure which can be placed where required.

Energy Saving In The Plantroom

All plants are individually designed and tailored for your needs. Energy efficiency can be achieved by selecting the following on your plant:

Electronic Expansion Valves (EEV’s)

Electronic expansion valves are used in refrigeration systems to precisely control the flow of refrigerant into the systems evaporator. They are the evolution of the traditional thermal expansion valve and operate using a much more sophisticated design.

Electronic expansion valves in conjunction with their controllers can adapt far easier to varying temperatures. Reducing pressure in the condenser when the outside temperature allows while also increasing the evaporator pressure as needed.

Variable Speed Drives

Most refrigeration systems inherently operate at reduced capacity. This is due to the fact the refrigeration motors that drive the compressor pumps and fans are designed to operate at maximum load conditions on a fixed speed.

A system that adopts a variable speed drive runs at only the capacity needed, instead of the inherent maximum load. This simple enhancement can deliver a cost saving of up to 30 – 50% in reduced energy consumption.

Compressor Soft Starters

A soft starter is effectively the electronic clutch for your refrigeration systems motors and/or compressors. The gradual uptake of power puts less load on the system and allows you to safely attach more equipment to a single supply.

A soft starter ensures that any given motor will only consume the energy required when off-load and can also switch motors off automatically when they are not required. This not only protects motors from excess heat & vibration but also greatly reduces the number of unscheduled breakdowns.

The Miniplex Design

The Miniplex is ideal for smaller format stores and can work on 5 evaporators using 1 compressor.

The system comes with a Brushless DC compressor and can yield up to 25% energy saving vs conventional systems.

The compressor is driven by the CAREL DC power+ inverter and pRack Hecu controller. The CAREL inverter and controller use advanced features to manage the compressor envelope and ensure safe operation. The controller is also connected to the MPXPRO controller installed on each refrigerated cabinet, in order to implement the floating suction function and optimise the set point in order to save energy

Why Miniplex?

Choosing Miniplex for complete management of small shops, such as convenience stores, means:

Energy Efficient

Achieving very high energy performance in the main areas of power consumption, such as refrigeration, air-conditioning and lighting.

Reduced Costs

Reducing operating costs for a fast return on investment.

Better Maintenance

Providing the best tools for preventive maintenance and increasing service levels to the end customer.

Great Quality

Guaranteeing excellent quality food preservation..